F4aT - Hydraulics laboratory

The fluid dynamics of hot fluids in fractured rock reservoirs play a central role in the exploitation of geothermal resources. The F4aT laboratory, which is funded by the DFG, was set up to clarify central, still unresolved questions regarding hydraulics, transport and the impact on fluid chemistry - especially for flows with high Reynolds numbers.

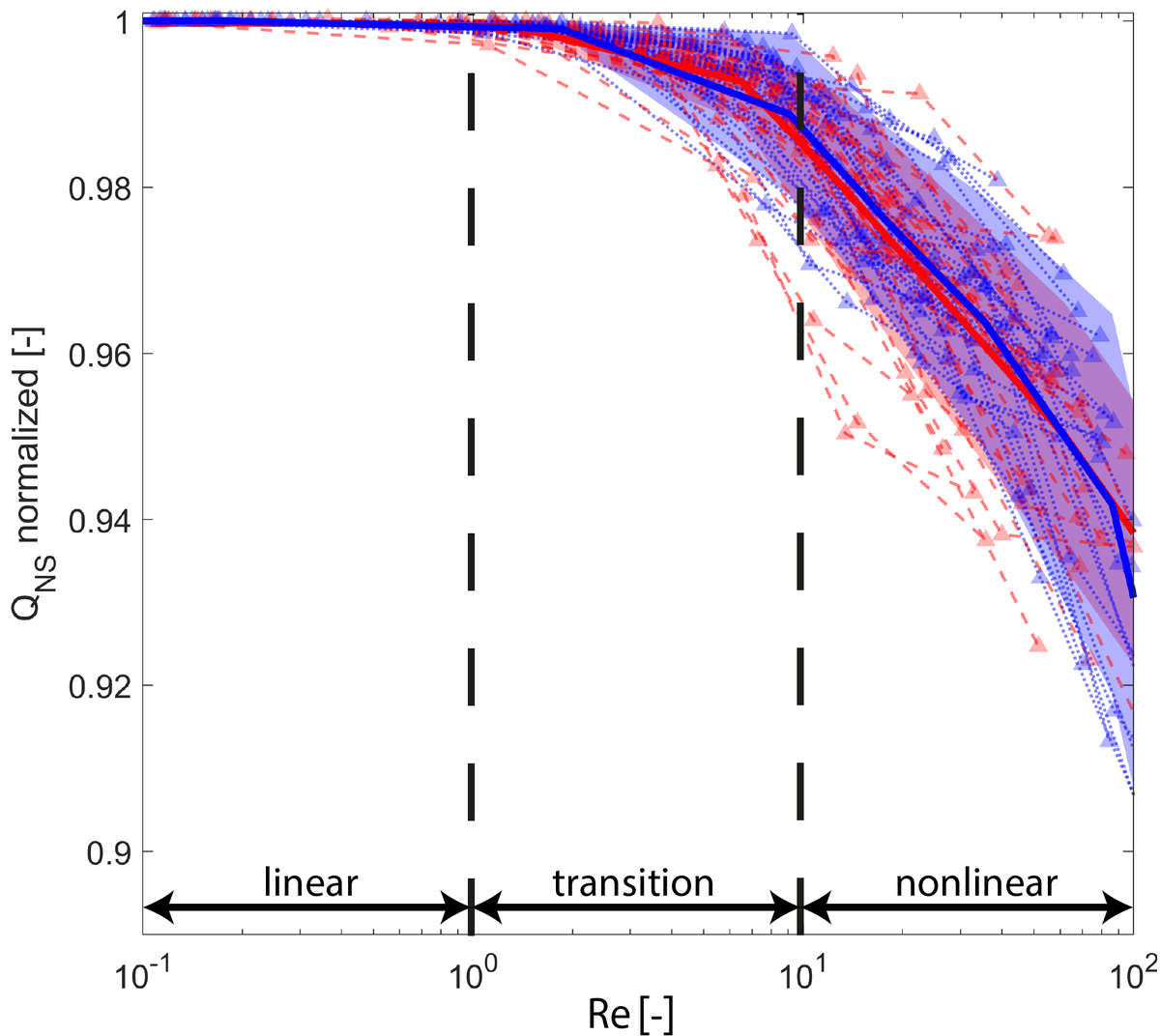

The F4aT - laboratory allows to perform flow experiments on rough fracture surfaces under geothermal typical high flow rates, which can lead to non-laminar, turbulence-like flows with Re >>100 (the critical Re for the consideration of non-linear conditions is often described with Re > 10). The aim is to identify experimentally at laboratory scale the sensitive parameters in the coupled system (flow rate, pressure, Reynolds number, aperture, shear offset, shear direction, roughness, etc.) and to quantify their influence on the flow conditions. The main research questions range from investigating the validity ranges of different flow laws, parameterization of constitutive flow laws and numerical models, identification of the relationships between roughness and hydraulics, to investigating the influence of channeling processes on the transport of heat and solutes.

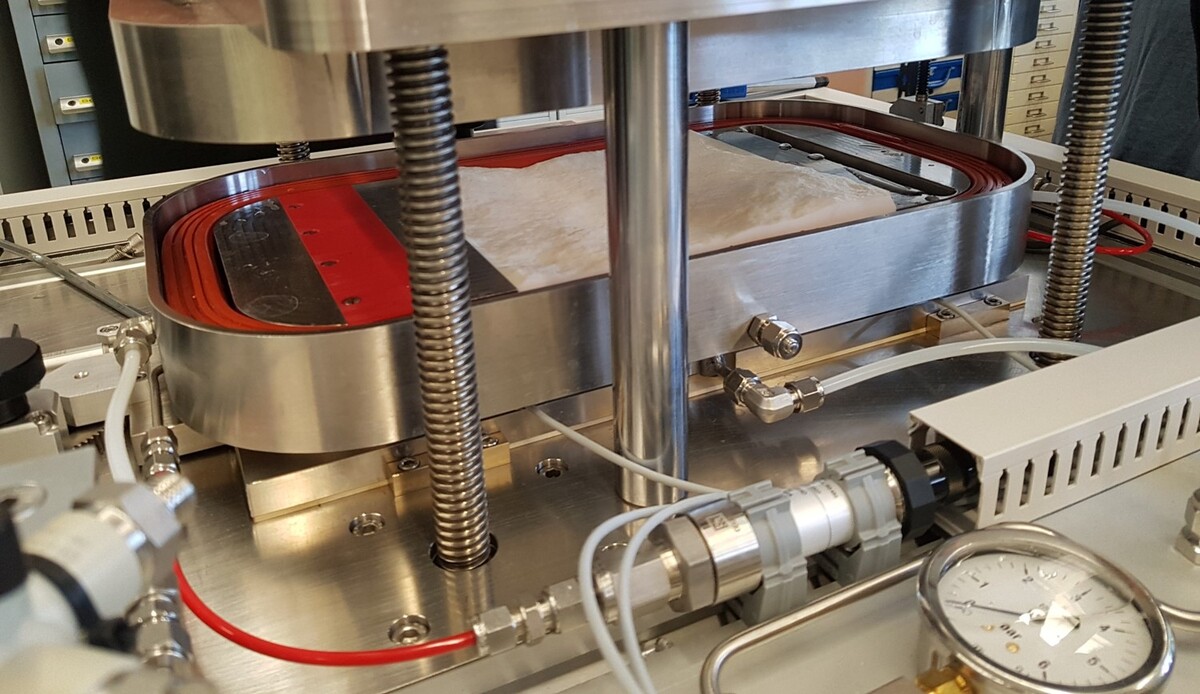

The experimental setup consists of a 3D scanner, a 3D printer, a thermal conductivity meter and the hydraulic test rig. Thus it is possible to measure the surfaces of natural rock samples by means of a scanner. These data serve as the basis for quantifying the roughness parameters and for producing the fracture sample by means of a 3D printer, which is then used to carry out the hydraulic tests. High accuracy pressure, flow and temperature sensors allow quantification of the hydraulic system or temperature transport properties of the sample. High-speed cameras allow the measurement and detection of turbulence, which can also be visualized by adding tracers using a bypass system.

This experimental setup puts us in the unique position to quantify hydraulics on rough fractures probabilistically on the experimental side, which was previously only possible using numerical models.