MALEG

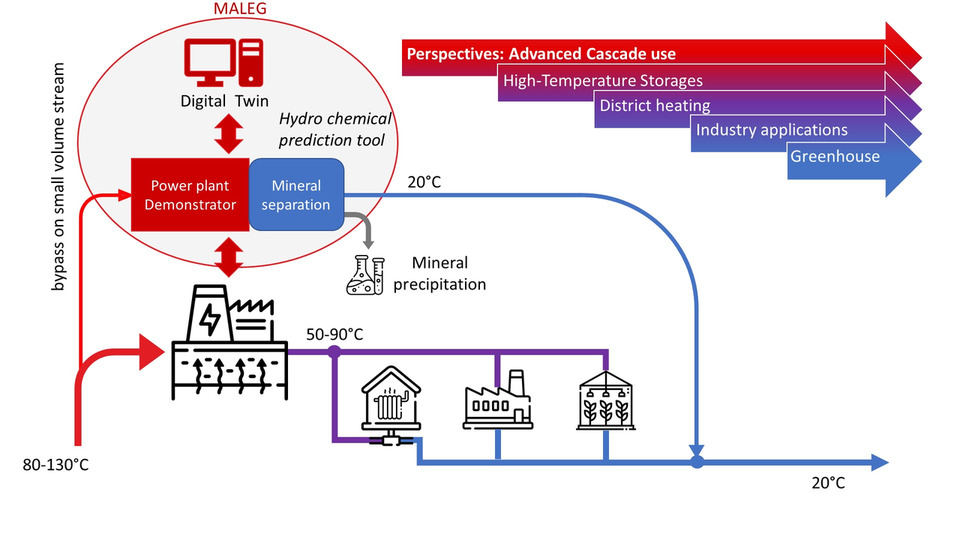

The machine learning for enhancing geothermal energy production (MALEG) project is a collaboration of multiple partners to develop an artificial intelligence (AI) to optimize power plant efficiency. To investigate enhanced heat extraction, an increased cooling of the thermal water is necessary. These changes in the operating parameters could lead to scalings and corrosion.

To train the AI, an on-site demonstrator ‘hardware-twin’ as well as a ‘digital twin’ are developed. The ‘hardware-twin’ emulate power plant processes, brine treatments and mineral extraction to investigate the occurrence of scaling and corrosion. The ‘digital-twin’ simulates the geochemical processes of these potential hazards.

In the end, the AI-based tool (MALEG) will be trained through extensive geochemical sampling campaigns, data collection and analysis of plant operating parameters. MALEG is able to predict the geochemical composition and the scaling potential based on live measurements of the geothermal brine optimizing the power plant efficiency.

Innovations of MALEG:

- The combination of hydrochemical reactive transport models with operational parameters

- The reproduction of a geothermal plant and the therein ongoing processes as a “digital twin“

- The development of a prediction tool for the determination of potential disturbing processes

- The development of a tool to make integrative and comprehensive predictions for the change of any conditions to increase the use of thermal energy

- The development of a machine learning tool, which improves continuously with the implementation of further data

- Process technology for geothermal brine treatment and mineral separation

- New approaches for the digitalization of water treatment processes and technologies

- The implementation of digital twins for simulation and control of hydraulic process technology in complex brine matrixes

R235

R235